East Carolina University graduates set out to leave their marks on the world. Four 2025 engineering graduates have already done just that.

Hannah Blackburn, Maranda Byrd, Lauren Simpson and Danielle Werts teamed with nonprofit Lev Legacy in Kinston to develop a protective attachment for a prosthetic foot that will be used by amputees in the Ivory Coast.

“I enjoy the impact that this project is going to have and that it’s actually going to be used,” Simpson said. “We’re not just creating this for no one. It actually has a real-world application that’s going to help a lot of people.”

From left, students Lauren Simpson, Danielle Werts, Hannah Blackburn and Maranda Byrd discuss their work to help amputees during the Department of Engineering Capstone Symposium in April at the Main Campus Student Center. (Photo by Ken Buday)

The students worked with Paul Sugg ’90 and son Tyler Sugg ’18, ’20. The ECU alumni own and operate EastPoint Prosthetics and Orthotics and Advanced 3D, a three-dimensional design and printing facility for the manufacturing industry as well as for prosthetic devices. With a desire to serve, they founded Lev Legacy, a nonprofit that supplies artificial limbs to patients. They have taken mission trips to serve amputees in the Ivory Coast since 2018. For their next trip at the end of July, they’ll be taking the new protective pad prototypes to help about 10 amputees.

“My team was especially moved by the fact that our design may help support the lives of individuals in developing African countries,” Blackburn said. “It has been a joy and a pleasure to work with EastPoint on this project. We look forward to supporting the work they do in any capacity.”

Finding the Solution

While parts of the Ivory Coast — officially called the Republic of Côte d’Ivoire — are developed, others are not, Paul Sugg said. He said the main reason behind amputations is the lack of quality health care in the country’s rural areas.

“When we step on a piece of glass, we go to the doctor and get it treated. When they step on a piece of glass, they have the potential to lose their foot because they don’t have access to the proper medical care,” he said. “If a snake bites you or a scorpion bites you, you have access to medical care here, and you’re probably going to be able to save that foot. Over there, you just won’t.”

Lev Legacy provides prosthetic limbs for those amputees, but the team began noticing an issue.

“What we were doing was gluing tread material right to the bottom of the feet,” he said. “What we did with East Carolina was to have them work on developing a foot covering that would go between the foot and the tread, so that way when the tread wears out, you can replace the tread and it doesn’t wear down the prosthetic foot itself and you won’t have to replace it. If you keep walking just on the prosthetic foot, you’ll wear it completely down due to the country’s rough terrain.”

The Advanced 3D team met Blackburn during a presentation to ECU’s Biomedical Engineering Society student organization, eventually leading to the senior capstone project that resulted in the foot covering prototypes.

“One of the main challenges was being able to balance the design that we wanted to do with the cost of it,” Werts said of the project. “We wanted it to be a perfect design that met all of the goals perfectly, but it would have to cost a lot more to fabricate, so we had to balance our objectives and the functions of the design versus the cost of what that would be and the cost of the material used.”

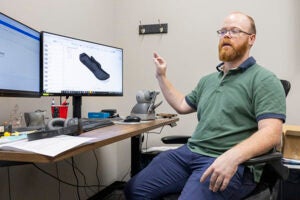

Tyler Sugg discusses the design of a protective attachment for a prosthetic foot in his office at Advanced 3D in Kinston. (Photo by Steven Mantilla)

Along with the design, the students had to account for the conditions in the west African nation.

“The environment over there is rough and the terrain is mostly red clay,” said Byrd, noting that most people in the rural country walk everywhere they go. “When it’s very rainy, it’s very muddy, but when it’s not, it’s extremely hard.”

Beyond adaptability to conditions, the insert had to be durable, as the mission team sees patients just once or twice a year. And Tyler Sugg warned the team of other factors to consider in their design.

“You have to design the foot shell so dirt can’t get into it and moisture can’t get into it, and even pests because there are all sorts of insects there and who knows what might try to nest inside of it,” he said.

The students created 10 designs, ranking them based on feasibility, accessibility of materials in the Ivory Coast, cost efficiency and durability. They narrowed the list to three, working with the team and testing the design with EastPoint patients to determine a final design.

“It really was neat to work with people who have this engineering background,” Tyler Sugg said. “Anytime we made any suggestions, they were able to make the modifications. I didn’t have to tell them how to do anything. It was really, really neat getting them here in the office to look at some patients actually walking on some different prototypes. You could just see all the ideas, all the gears spinning in the students, and then watching them initiate changes in their design.

“It was amazing some of the different prototypes and iterations they came up with. This thing could have looked completely different a week from now, and that would be perfectly fine. It was very exciting, and they were able to hone it and get us to the best possible version that met as many of our goals as could be expected. We even found some affordability and printability that we hadn’t even envisioned to begin with.”

Lessons Learned

The senior engineering capstone project is designed to allow students to apply what they’ve learned in the classroom to a real-world project, further preparing them for engineering careers. The students said the project did exactly that.

A patient tests a protective attachment for a prosthetic foot outside EastPoint Prosthetics and Orthotics in Kinston. (Contributed photo)

“This project has given me and the team insight into project management, engineering design, and resource allocation and utilization,” Blackburn said. “In connecting with and talking to numerous ECU engineering alumni, I have learned that project management is a key skill in all fields. The team and I were able to identify and establish realistic goals for our project, maintain a timeline and update sponsors regularly, and collaborate with numerous groups to produce the best design solution for this project.”

Werts said teamwork played an important role in getting the job done.

“Some of the issues we faced as a team, we were able to talk through the challenges that we were having, listen to different ideas, compromise when we had different ideas and apply those solutions,” she said.

Simpson said the project gave her confidence to conquer challenges she’ll face on the job.

“Problem-solving in general — there were a lot of challenges with this project, and it was nice to be able to overcome them and learn from them,” she said.

Dr. Shunafrica Chambers, associate professor in the Department of Engineering, served as the faculty advisor on the project.

“The team was very dedicated to the project and very receptive to any feedback,” she said. “I am extremely proud of them. Everyone in the team contributed to the project equally, which was apparent because any one of them could explain the project from top to bottom. I am very impressed by their initiative and dedication because Hannah, Maranda, Lauren and Danielle are part of the cohort of students whose learning environment was impacted by COVID, but they pushed through and gained mastery of engineering content, which was essential to the success of their project.”

Completing the Mission

Paul Sugg thanked the students for work that he said would help Lev Legacy make a difference in the lives of amputees.

“We’re halfway around the world, but we’re helping people,” he said. “The coolest thing about everything we do is that the highest technology in the world is going to the poorest people in the world.”

As an ECU alumnus, he recognizes the value of service, not only to amputees but also to students, teaching them lessons he hopes they will pay forward as alumni themselves.

“It’s Pirates helping Pirates,” he said. “We’re alumni, and that’s an important thing to me. Those young women we worked with were just awesome. They were really top-notch students. All of them were very professional. They filled a need, providing a product beyond their local borders. I think they came up with a good thing to help amputees in a remote portion of West Africa to live life more independently. Service has no boundary.”

.jpeg)

-1.png)