Tempus 3D, an industrial 3D printing company based in Trail, British Columbia, is advancing sustainability in additive manufacturing through the development of an innovative plastics recycling process. This new initiative is being supported by a $250,000 grant from the CleanBC Plastics Action Fund, an investment that underscores the company’s leadership in environmentally responsible practices within the region’s manufacturing sector.

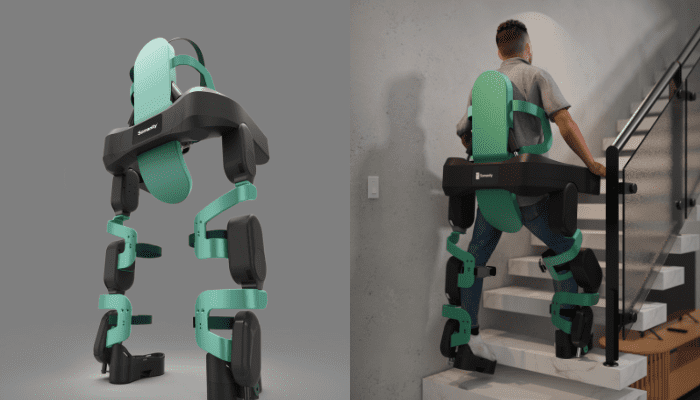

The funding will enable Tempus 3D to create a comprehensive recycling system targeting difficult-to-process materials, such as nylon, which is commonly used in 3D-printed products for industries like orthotics, prosthetics, and other high-performance medical devices. Traditionally, these specialized printed components have presented a significant waste challenge, as they are largely unsuitable for existing recycling streams and have often been relegated to landfills at the end of their usable life.

“This has become particularly impactful with the mass adoption of 3D printing in industries like orthotics, prosthetics, and other medical devices,” said Robert Bleier, the CEO of Tempus 3D, in an interview with the Trail Times. “The process that Tempus is building will enable us to provide a fully circular solution for our customers and a novel recycling option for otherwise unrecyclable parts for the broader market.”

The project’s objectives are multifaceted. By developing a closed-loop recycling process, Tempus 3D aims to drastically reduce the consumption of virgin plastics, divert significant volumes of post-consumer and post-industrial waste from landfill, and strengthen the circular economy within the Kootenays. This involves recovering and reprocessing not only production waste but also degraded powders and discarded products, such as custom orthotics, thereby extending the lifecycle of valuable plastic resources.

Recently, the three-person Tempus 3D team invited the Trail Times for a demonstration at their facility, showcasing the practical aspects of their recycling process. CEO Robert Bleier, production lead Jordon Shupe, and manufacturing advisor Jonathan Guercio walked visitors through the production floor, highlighting the large bins of virgin plastic powder used in their selective laser sintering (SLS) systems. Over multiple print cycles, this powder degrades and loses its printing quality, necessitating disposal in traditional workflows. With the help of the CleanBC grant, Tempus 3D is developing a process to rejuvenate and recycle this degraded material, returning it to the supply stream for future manufacturing runs.

Beyond reducing internal waste, the company is also exploring solutions for recycling end-of-life products manufactured at their facility. This means that items like custom orthotics can be collected after use, broken down, and remanufactured into new parts—further reducing the overall environmental footprint and supporting sustainable product stewardship.

Operating for five years from the Selkirk Technology Access Centre on Highway Drive in Glenmerry, Tempus 3D has fostered strong relationships with the local educational community, regularly collaborating with students enrolled in digital design and fabrication programs at Trail campus. Both Shupe and Guercio, for example, are recent graduates who have transitioned from academia into roles with significant responsibility at the company.

It is notable that Tempus 3D primarily acts as a production partner, receiving sophisticated digital design files from clients across Canada and delivering on-demand manufacturing of custom plastic and metal components. This approach inherently minimizes waste and supports agile, efficient production cycles. The step into recycling, therefore, is a natural extension of the company’s commitment to supporting sustainable, regionally anchored manufacturing.

“Tempus 3D is doing some incredibly impressive stuff right here in the Kootenays,” said Kootenay-Monashee MLA Steve Morissette, who visited the company’s Glenmerry site. “Our province is supporting innovative businesses by helping them make greener waste management decisions.”

Tempus 3D’s grant comes as part of a larger $8-million investment from the B.C. government in 2025, under the CleanBC Plastics Action Fund, to support 34 forward-thinking plastics management projects. These funded initiatives are designed to increase recycling, facilitate reuse and repair of plastic products, drive the replacement of single-use plastics, and ultimately create local green jobs. This year’s recipients span a diverse spectrum, from establishing reusable cup programs at large events and expanding textile recycling operations to piloting zero-waste retail models and building shared community dishwashing infrastructure. Since the inception of CleanBC Plastics Action Fund in 2020, more than $35 million has been invested in almost 100 projects, already leading to the creation of over 240 full-time jobs, with continued growth and innovation expected as new projects come online.

.jpeg)

-1.png)